Candy Dispenser

In my Introduction to Product Realization course, the final project was to make a candy dispenser. There were a few design specifications that had to be met for the project which added some additional challenge:

-

Can store up to twenty candies

-

The "candies" were plastic spheres, about 1mm in diameter

-

-

Dispense the candies one at a time

-

Reset set itself automatically

-

Have some form of rotary motion

-

Candies must have a designated release spot

-

Components had to be 3D printed or laser cut

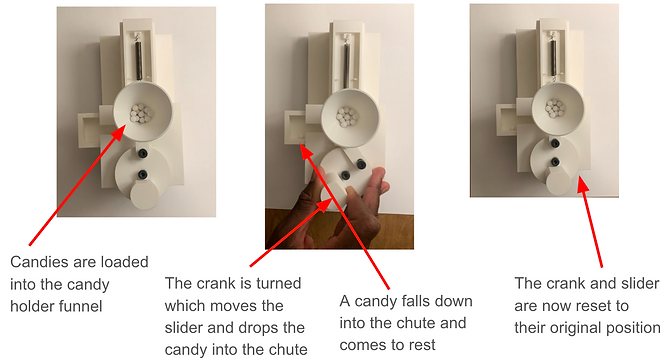

I started this project by making some initial sketches of potential ideas. I also had to research how I wanted to incorporate a mechanism that used rotary motion. I decided on using a crank and slider, where the user would turn the crank, and the slider would push the candies out of the machine. I worked then to create early rapid prototypes of the the key components of my machine:

-

The candy holder, which would need to be able to hold 20 pieces of candy

-

The slider, which pushes candy into a hole for dispensing, with a spring attached to it for resetting.

-

The crank and slider, which will translate the rotary motion of the crank into the linear motion of the slider.

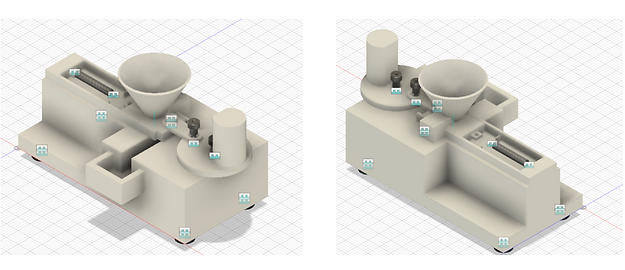

Next, I worked to create a basic 3D model of my candy dispenser in CAD. After prototype testing, I decided to make the candy holder more of a funnel shape, and added in the base and candy catcher at the end of the chute as well.

The next step in the design process was to create a functional prototype, where some of the parts were manufactured and some of the parts were still made from the rapid prototyping materials.

After this I modeled the entire assembly in CAD so that I could begin 3D printing my components.

After creating 3D printing all of the components I assembled the candy machine. Then I tested my entire candy machine for its functionality. I also had to create an engineering drawing for one of my components and an exploded BOM. This project was successful as I was able to create a fully functional candy machine that met all of the design specifications.